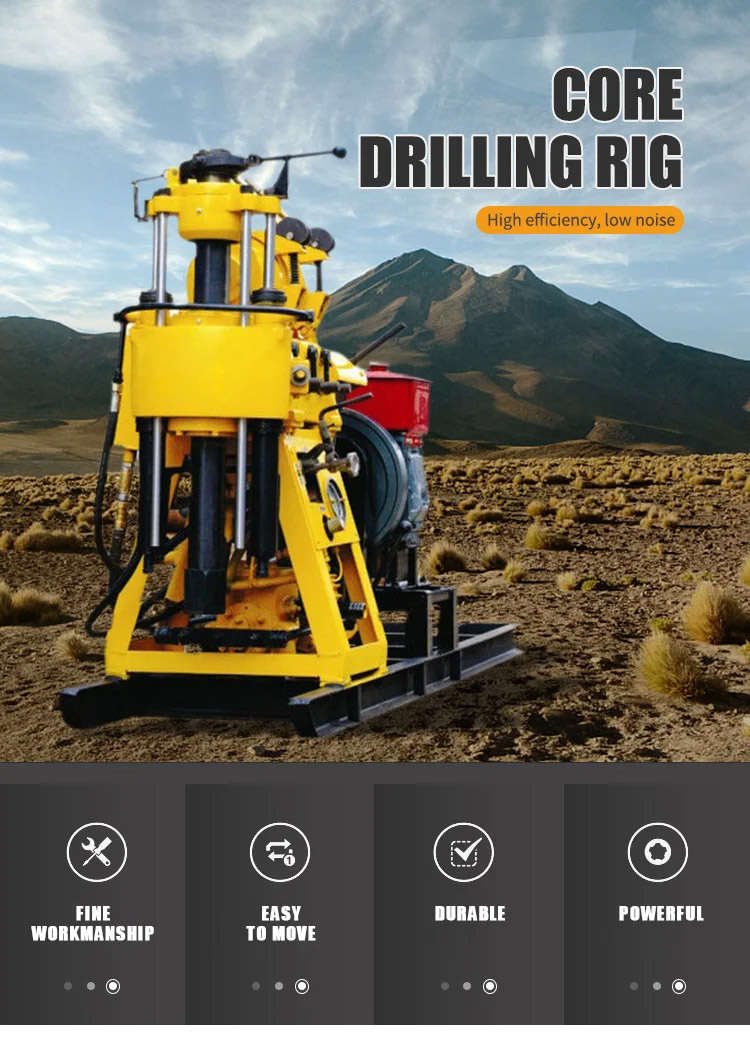

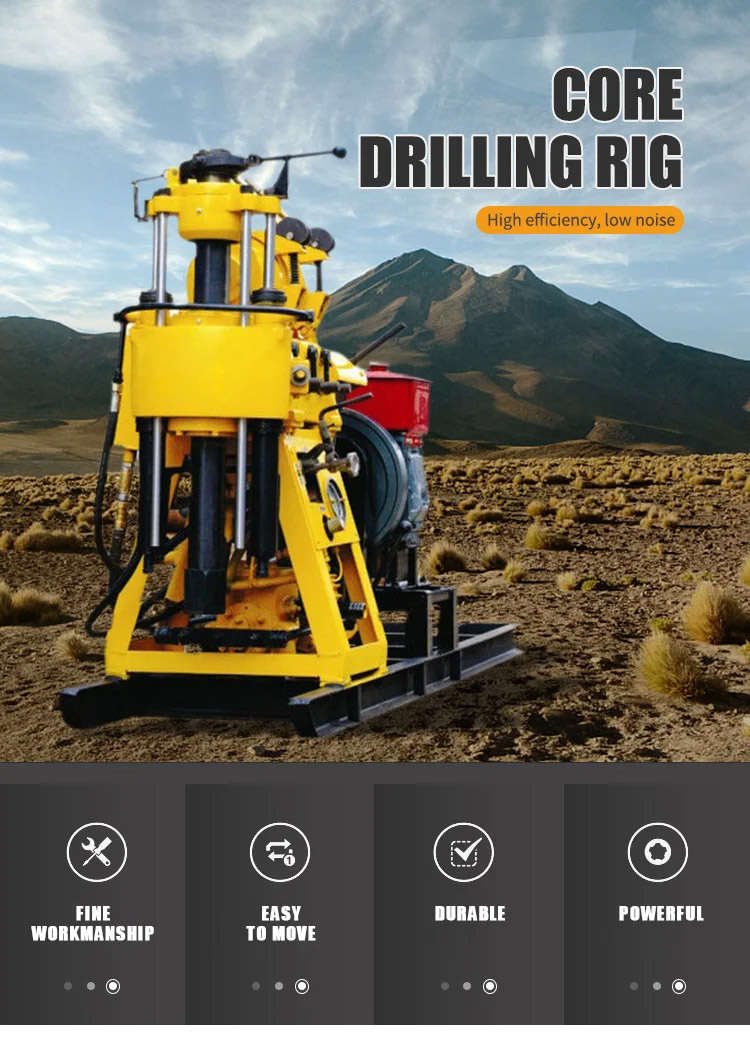

XY-160 Water well drilling machine quality assurance

Rotary Drilling Rigs: Utilize a rotary motion to drill, making them effective for deep wells. They are versatile and can work in diverse geological conditions.

- XY-160

- ZHUOXIN

- water well drilling machine

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Direct Push Technology: These rigs use a hydraulic hammer to advance a hollow-core probe into the soil. They are efficient for soil sampling and shallow water well drilling.

Description

Water well drilling rigs are specialized mechanical systems designed for drilling boreholes into the earth to extract water. These rigs play a crucial role in accessing subterranean water resources, which are vital for residential, agricultural, and commercial uses.

Rotary Drilling Rigs: Utilize a rotary motion to drill, making them effective for deep wells. They are versatile and can work in diverse geological conditions.

Cable Tool Rigs: Employ a pounding action to fracture the earth. Ideal for hard rock formations, they are known for their durability and depth capabilities.

Direct Push Technology: These rigs use a hydraulic hammer to advance a hollow-core probe into the soil. They are efficient for soil sampling and shallow water well drilling.

Drilling Tower or Derrick: A tall structure that holds and stabilizes the drilling machinery.

Drill Bits: Cutting tools at the end of the drill string that penetrate the ground; available in various designs for different soil conditions.

Drill Pipes: Tubular sections that transmit rotational force to the drill bit and allow for the removal of the drilled material.

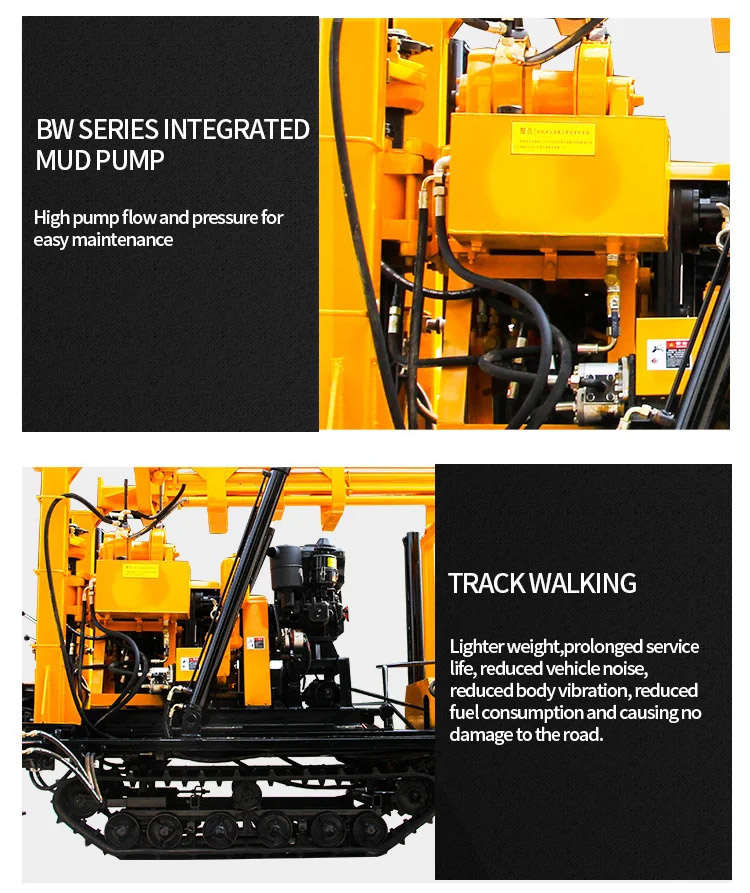

Mud System: Includes a mud pump and a mud pit; used in rotary rigs to circulate the drilling fluid, which cools and lubricates the drill bit and carries the cuttings to the surface.

Conclusion

Water well drilling rigs are essential in tapping into underground water sources, providing a lifeline for various sectors. The continuous innovation in drilling technology not only improves the efficiency and safety of these operations but also ensures sustainable management of one of our most precious natural resources: water.

This article offers a thorough overview of water well drilling rigs, emphasizing their types, functionality, technological advancements, and their pivotal role in sustainable water resource management.

Cable Tool Drilling Rigs: Also known as "pounders," these rigs use a heavy string of drilling tools to repeatedly lift and drop a bit into the wellbore. This action crushes and breaks the rock at the bottom of the hole, and the debris is removed with a bailer.

Direct Push Rigs: These rigs use a hydraulic hammer to drive a heavy, hollow pipe into the ground. They are typically used for shallow wells and environmental investigations.

Mast: A tower-like structure that supports the drill bits and drilling machinery.

Drill Bits: Tools attached to the end of the drill string that break and penetrate the soil or rock.

Drill Pipes: Hollow tubes that connect the rig to the drill bit, allowing for the removal of drilled material.

Mud Pumps: Used in rotary rigs to circulate drilling fluid, which cools the drill bit and removes drill cuttings.

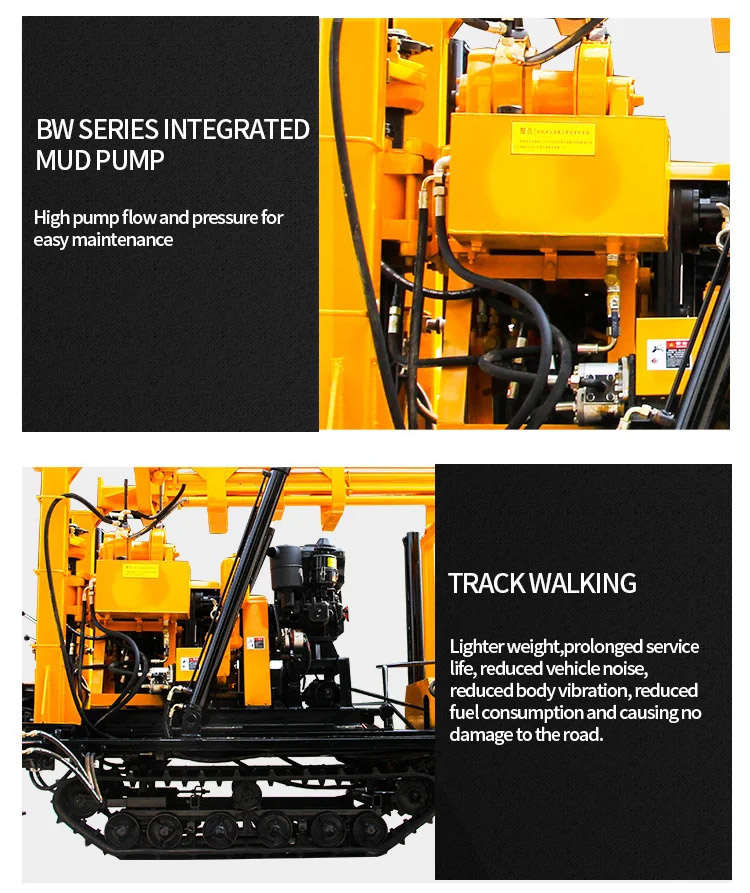

Power System: Includes engines and motors that power the drilling process.

Rotary Drilling Rigs: Utilize a rotary motion to drill, making them effective for deep wells. They are versatile and can work in diverse geological conditions.

Cable Tool Rigs: Employ a pounding action to fracture the earth. Ideal for hard rock formations, they are known for their durability and depth capabilities.

Direct Push Technology: These rigs use a hydraulic hammer to advance a hollow-core probe into the soil. They are efficient for soil sampling and shallow water well drilling.

Drilling Tower or Derrick: A tall structure that holds and stabilizes the drilling machinery.

Drill Bits: Cutting tools at the end of the drill string that penetrate the ground; available in various designs for different soil conditions.

Drill Pipes: Tubular sections that transmit rotational force to the drill bit and allow for the removal of the drilled material.

Mud System: Includes a mud pump and a mud pit; used in rotary rigs to circulate the drilling fluid, which cools and lubricates the drill bit and carries the cuttings to the surface.

Conclusion

Water well drilling rigs are essential in tapping into underground water sources, providing a lifeline for various sectors. The continuous innovation in drilling technology not only improves the efficiency and safety of these operations but also ensures sustainable management of one of our most precious natural resources: water.

This article offers a thorough overview of water well drilling rigs, emphasizing their types, functionality, technological advancements, and their pivotal role in sustainable water resource management.

Cable Tool Drilling Rigs: Also known as "pounders," these rigs use a heavy string of drilling tools to repeatedly lift and drop a bit into the wellbore. This action crushes and breaks the rock at the bottom of the hole, and the debris is removed with a bailer.

Direct Push Rigs: These rigs use a hydraulic hammer to drive a heavy, hollow pipe into the ground. They are typically used for shallow wells and environmental investigations.

Mast: A tower-like structure that supports the drill bits and drilling machinery.

Drill Bits: Tools attached to the end of the drill string that break and penetrate the soil or rock.

Drill Pipes: Hollow tubes that connect the rig to the drill bit, allowing for the removal of drilled material.

Mud Pumps: Used in rotary rigs to circulate drilling fluid, which cools the drill bit and removes drill cuttings.

Power System: Includes engines and motors that power the drilling process.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)