- Home >

- Product >

- Excavator >

- Wheel excavator >

- View Details

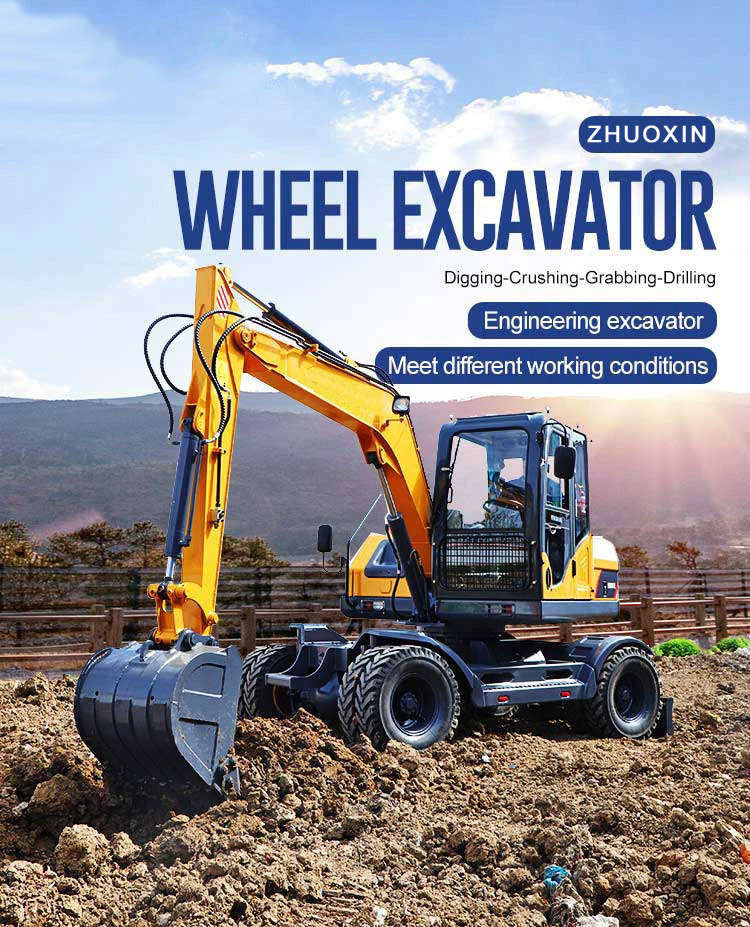

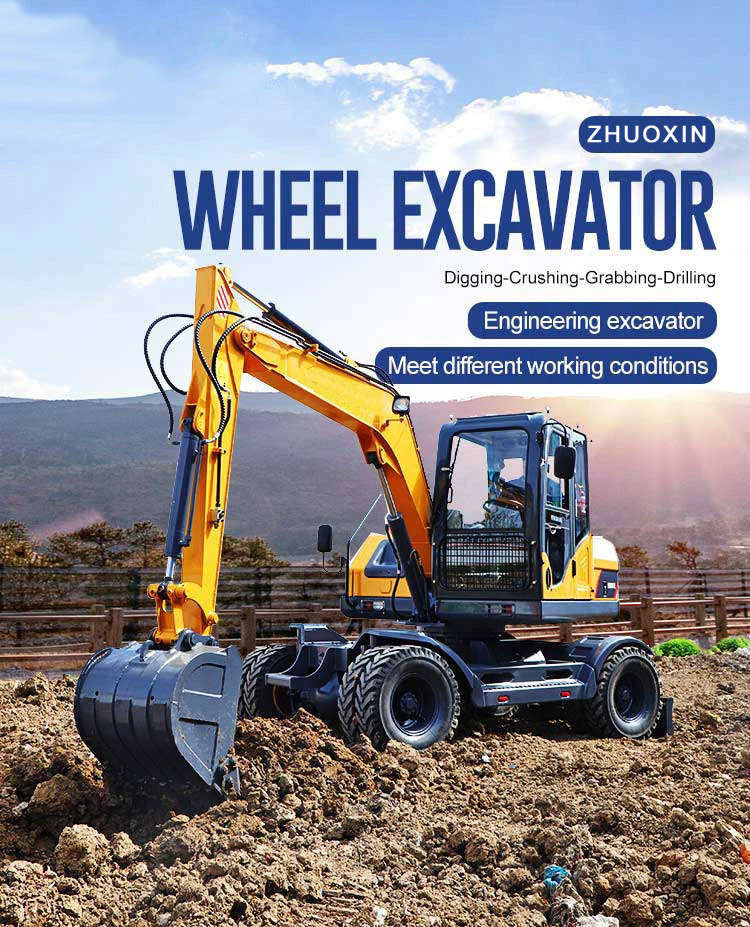

HK-40 Wheel excavator factory outlet

Bucket wheel excavators are used whenever large quantities of materials need to be processed on an ongoing basis. One of the main areas of application is in lignite mining. In this case, bucket wheel excavators are primarily used to remove soft rock.

- HK-40

- ZHUOXIN

- shandong.china

- TT, Paypal, Credit card, Western union

- +86-15163766288

- Environmental Considerations: Wheeled excavators tend to have a lower ground pressure which results in less soil compaction and environmental impact, particularly in sensitive areas.

Description

Wheel type excavator is suitable for road administration or small projects in the city, with high driving speed, strong site adaptability, and flexible transition. Wheeled excavators are general-purpose excavators. The main difference is that instead of running on tracks, they run on wheels. An advantage of a wheeled excavator is that it can be driven from one job site to another even on a road, while crawler excavators running on tracks are usually carried on a trailer for long-distance travel.

1.This mini wheel excavator has beautiful appearance, high configuration, superior performance, low fuel consumption and wide working range.

2.The hydraulic system based on load-sensing technology has good operation performance and soft movements, which can prove the precise operation.

3.360° rotation is suitable for safe operations in small spaces, such as: loosening of soil in vegetable greenhouses, greening of campuses in municipal departments, tree planting openings in orchard nurseries, crushing of concrete pavements, mixing of sand and gravel materials, and construction in narrow places.

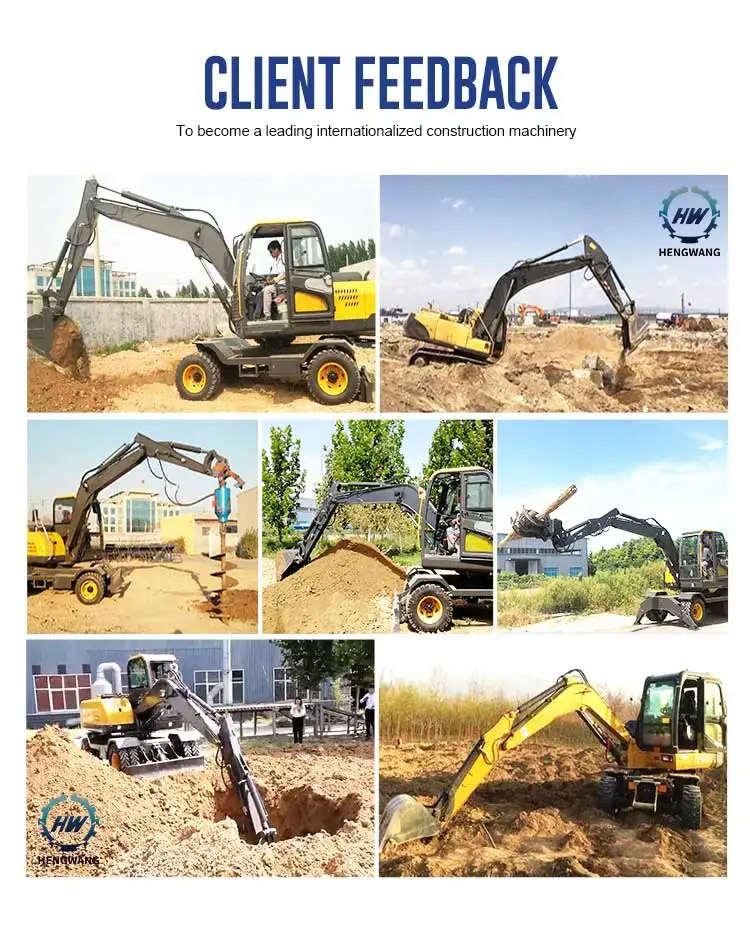

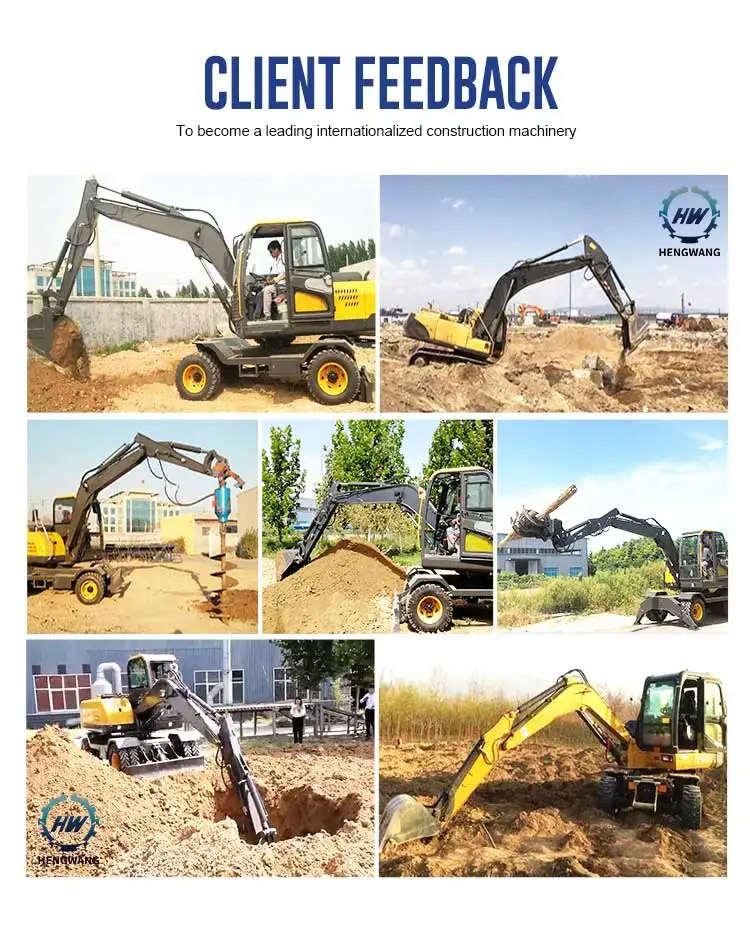

We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.

Excavators, also known as diggers, are heavy equipment machines that are commonly used in construction and excavation projects.

1. Versatility: Excavators are designed to be versatile and adaptable to various types of work environments. They can be used for activities such as digging, demolition, lifting, and grading.

2. Power: Excavators are powerful machines that are capable of handling heavy loads and excavating hard materials such as rock and clay.

3. Mobility: Excavators are equipped with tracks or wheels that allow them to move over different types of terrain, making them useful in various construction and excavation projects.

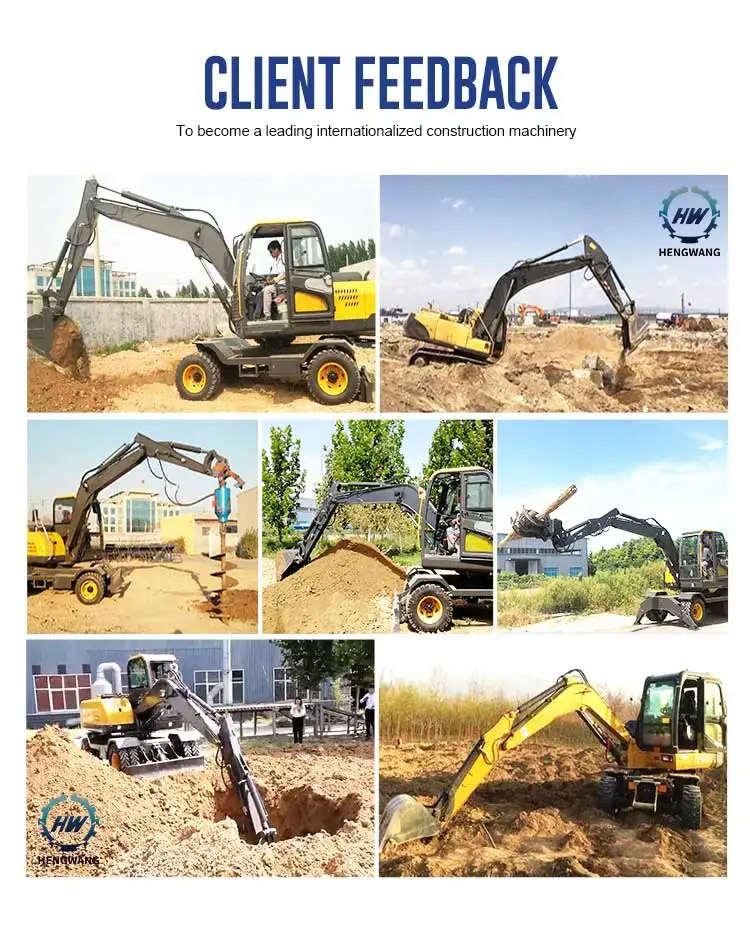

Wheel type Excavator Goods Delivery

Based on good quality and decades of experience, the Wheel type Excavator which is manufactured by YONGHENG was exported to different countries. The Wheel type Excavator will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

Safety Protocols: Modern safety features include enhanced operator cabins for visibility and protection, along with systems like rear-view cameras and proximity sensors to prevent accidents.

Conclusion

Wheeled excavators represent a blend of mobility, versatility, and technological innovation, making them a valuable asset in various sectors. As technology evolves, these machines continue to become more efficient, environmentally friendly, and safer, thereby solidifying their role in modern construction and engineering projects.

Wheeled excavators, a vital piece of machinery in the modern construction and civil engineering industries, offer a unique combination of power, flexibility, and efficiency. These excavators are mounted on wheels rather than traditional tracks, making them particularly suited for a variety of tasks across different terrains.

Design Characteristics

Wheel-based Mobility: The primary feature of wheeled excavators is their wheel-based mobility, allowing for smoother movement on concrete and asphalt, reducing damage to these surfaces compared to track-based systems.

Structural Components: A typical wheeled excavator consists of a rotating cab, an articulated arm, a bucket, and a set of four to eight wheels. The cabin offers comfort and safety for the operator with advanced control systems.

Attachment Versatility: Similar to tracked excavators, wheeled variants can operate with various attachments, including different types of buckets, breakers, and even augers, enhancing their utility in diverse operations.

Operational Advantages

Speed and Efficiency: One of the main advantages of wheeled excavators is their ability to move quickly between job sites without the need for additional transportation. This mobility saves time and increases efficiency in projects.

Urban and Road Work: These excavators are particularly advantageous in urban settings and for road works, where their mobility and reduced impact on paved surfaces are crucial.

1.This mini wheel excavator has beautiful appearance, high configuration, superior performance, low fuel consumption and wide working range.

2.The hydraulic system based on load-sensing technology has good operation performance and soft movements, which can prove the precise operation.

3.360° rotation is suitable for safe operations in small spaces, such as: loosening of soil in vegetable greenhouses, greening of campuses in municipal departments, tree planting openings in orchard nurseries, crushing of concrete pavements, mixing of sand and gravel materials, and construction in narrow places.

We provide more optional parts to complete more kinds of work. We provide a variety of work tools such as grabs, forks, pulverizers, etc. to meet your various application needs. In addition, a variety of fixtures are provided to optimize the performance of the machine. The auxiliary hydraulic lines are arranged on the base of the boom, making the auxiliary hydraulic circuit easier to install, thereby reducing the time, parts and costs required for installing work tools.

Excavators, also known as diggers, are heavy equipment machines that are commonly used in construction and excavation projects.

1. Versatility: Excavators are designed to be versatile and adaptable to various types of work environments. They can be used for activities such as digging, demolition, lifting, and grading.

2. Power: Excavators are powerful machines that are capable of handling heavy loads and excavating hard materials such as rock and clay.

3. Mobility: Excavators are equipped with tracks or wheels that allow them to move over different types of terrain, making them useful in various construction and excavation projects.

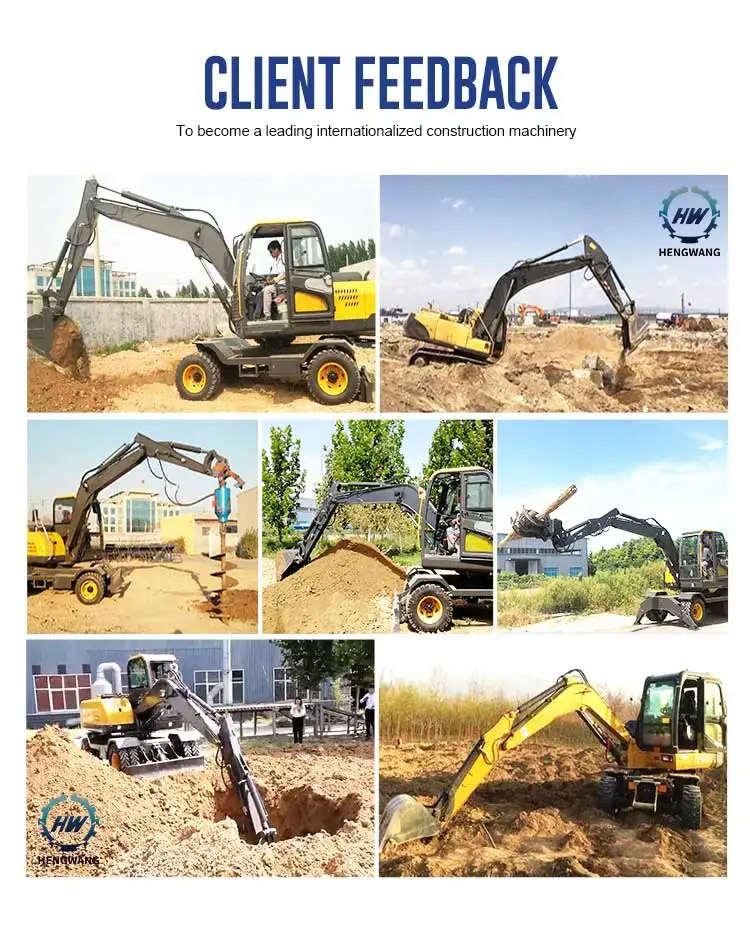

Wheel type Excavator Goods Delivery

Based on good quality and decades of experience, the Wheel type Excavator which is manufactured by YONGHENG was exported to different countries. The Wheel type Excavator will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

Safety Protocols: Modern safety features include enhanced operator cabins for visibility and protection, along with systems like rear-view cameras and proximity sensors to prevent accidents.

Conclusion

Wheeled excavators represent a blend of mobility, versatility, and technological innovation, making them a valuable asset in various sectors. As technology evolves, these machines continue to become more efficient, environmentally friendly, and safer, thereby solidifying their role in modern construction and engineering projects.

Wheeled excavators, a vital piece of machinery in the modern construction and civil engineering industries, offer a unique combination of power, flexibility, and efficiency. These excavators are mounted on wheels rather than traditional tracks, making them particularly suited for a variety of tasks across different terrains.

Design Characteristics

Wheel-based Mobility: The primary feature of wheeled excavators is their wheel-based mobility, allowing for smoother movement on concrete and asphalt, reducing damage to these surfaces compared to track-based systems.

Structural Components: A typical wheeled excavator consists of a rotating cab, an articulated arm, a bucket, and a set of four to eight wheels. The cabin offers comfort and safety for the operator with advanced control systems.

Attachment Versatility: Similar to tracked excavators, wheeled variants can operate with various attachments, including different types of buckets, breakers, and even augers, enhancing their utility in diverse operations.

Operational Advantages

Speed and Efficiency: One of the main advantages of wheeled excavators is their ability to move quickly between job sites without the need for additional transportation. This mobility saves time and increases efficiency in projects.

Urban and Road Work: These excavators are particularly advantageous in urban settings and for road works, where their mobility and reduced impact on paved surfaces are crucial.

Tags

Get the latest price? We'll respond as soon as possible(within 12 hours)